Now that we have finished the book Rowed Trip, we are moving through a backlog of chores which includes completing our home renovations and improving its energy efficiency.

The common adage the best things in life are free applies to many things, but home renovations are typically not included. We found otherwise. I crunched some preliminary numbers and instead of a hefty price tag discovered that all our improvements– new kitchen cabinetry, flooring, lighting, walls, insulation, windows, doors, paint, thermostats and a host of other stuff – will cost us nothing. And that’s not an April Fools’ Day joke. We’re yanking our dated seventies home into this decade for free and eventually the improvements will even make us money (and not through hopes of appreciation in an unpredictable market).

Our free home makeover is a three-stage process. First, we are taking advantage of the numerous energy efficiency grants available, along with the home renovation credit. Secondly we are keeping costs low by buying things on sale. Finally, and most importantly, we are making substantial energy-saving changes to our home that will cut more than one-third off our annual energy consumption. This means that in eighteen years the value of our energy savings will equal the cost of our entire home renovation project.

We have also been careful in the types of changes we’ve made. Our projects are geared to offer maximum energy savings on the dollar to keep costs at a minimum and done using recycled and eco-friendly materials. Our goal is to show that going green is not a step down or an added expense, but instead can improve your living standard as well as treading lighter on the environment. Beginning next month we’re launching a web series that breaks down the process of our free home reno and shares details on how you can make your home environmentally friendly and save money. Our first article will explain how we increased the insulation level in our attic for free (and that’s before factoring in energy savings!).

Another aspect of sustainable living critical to us is the clothing we wear. In our expeditions, as well as local outdoor excursions, we need technical clothing that wicks moisture, breathes, keeps us dry, warm, cool and comfortable, yet is also made in an eco-friendly manner. This is a tough request, especially when dealing with environments that range from blistering heat to arctic winter. Our clothing partner Helly Hansen manages to excel in every clime. And now they’ve taken their products to another level by creating a new line of clothing, Ekolab; even more environmentally sound and just as functional. Ekolab uses 100% organic cotton, recycled fleece, zippers and trim, and waterproof breathable fabrics created with fluorocarbon-free DWR coatings instead of harmful PTFE chemicals. They’re also working on minimizing the impact of shipping by creating clothing near the point of sale and using efficient transportation systems.

Of course these values are not new to Helly Hansen; after all they are based out of Norway, ranked as the world’s third most progressive country in environmental management (2008 Environmental Performance Index – Yale and Columbia Universities). Nurtured within this culture of strict environmental stewardship, Helly Hansen has always produced clothing in a sustainable manner. As other companies modify operations to meet public demand, Helly Hansen is simply showcasing core values always present within the company.

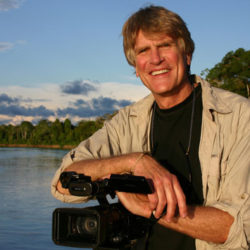

We’re proud to be a part of the Ekolab project. It’s the kind of clothing we’d design if we could, which of course we can’t, but we are good at testing it. A few weeks ago we met up with Helly Hansen’s film crew to talk about sustainable clothing, living on Vancouver Island and philosophies in conservation.

Of course there’s no point having technical outdoor clothing without exciting activities to go on. Many have been asking when plans and kits for the towable rowboats we used on our Scotland to Syria expedition will be available. Well, we’re on track for having the kits ready this fall. For those unfamiliar with kit boats, it’s the most economical way to produce a quality strong vessel. Kind of like Ikea furniture (albeit a little more work), the components for the vessel are pre-cut and final assembly is done at home in about 50-100 hours. We’re developing two different models to start – an open style wherry, and the Expedition model which will be identical to the boats we used on our Scotland to Syria voyage.

Our well-travelled boats, Niobium and Tantalum, will be returning to the water soon and in the meantime we’ve been exploring Vancouver Island’s wilderness by foot. We hope that you too are enjoying life; boating, hiking, skiing, biking, and whatever pursuits bring you happiness. Happy April Fools’ Day and have a wonderful month.

– Colin